Helping a market leading packaging machinery manufacturer capture employee knowledge to help reduce downtime and improve customer productivity and profitability.

The challenge

With global customers like Heinz, Nestlé and GSK, Universal Pack isn’t just the leading manufacturer of packaging machines. It’s the unsung hero keeping world-wide production lines humming, 24/7/365. Their machines are often one of several on a production line and keeping them operational is crucial to their customers success.

Imagine trying to fix a complex machine with little to no record of its fault history or troubleshooting steps.

Universal Pack’s engineers are very well trained, with many years of experience, and access to a broad selection of documentation including user manuals, SOP’s, maintenance, service and parts replacement reports to help them understand the history of a machine. However, these documents, like most other businesses, are stored in filing cabinets or hard to access Sharepoint repositories. This means the engineers need to hunt down the information. And that takes time. That time costs their customers money in lost production and revenue. However, Universal Pack are not unique.

Universal Pack is often one of several machine suppliers to a customer, so their challenge can be multiplied across a factory with dozens of machines and several production lines. Often manufacturers struggle to achieve 60% uptime on their lines as different machines fail for different reasons.

The Dave effect

Every business has a “Dave”. You know the one. They’ve been around for years and know everything about how things really work. When something breaks, everyone says, “Go and ask Dave.”

He’s the walking manual. The fixer. The one with all the little tricks that keep everything running smoothly. But one day…Dave won’t be there. And when he goes, so does a lifetime of knowledge.

And that’s what happened to Universal Pack.

Their Dave really was called Dave, and after 30 years of dedicated service it was time for Dave to retire. And take all his knowledge with him. Luckily for Universal Pack, 3 weeks after his retirement he asked to come back to work part time. But those 3 short weeks had shown Universal Pack that they had a Dave shaped hole in their business knowledge. Not the documentation, but the unwritten experience Dave had built up over many years of maintaining and repairing machines.

The solution

That’s where Maverick Partners came in. We were tasked with coming up with a cost effective solution that could help Universal Pack audit their existing recorded knowledge bank and start to fill the gaps.

We ran a short one week discovery project to understand how Universal Pack ran their business, gathered their information, and what technology they used. We then designed a solution that helped them start collating information and empowering employees with on the spot access to documentation to carry out service, maintenance and repairs faster.

We recommended using GCP’s new Vertex AI platform to underpin the solution. We leveraged our GCP partnership to secure some funding to support the build of a proof of concept to test out a possible solution with working information and to gain crucial user feedback for a future MVP.

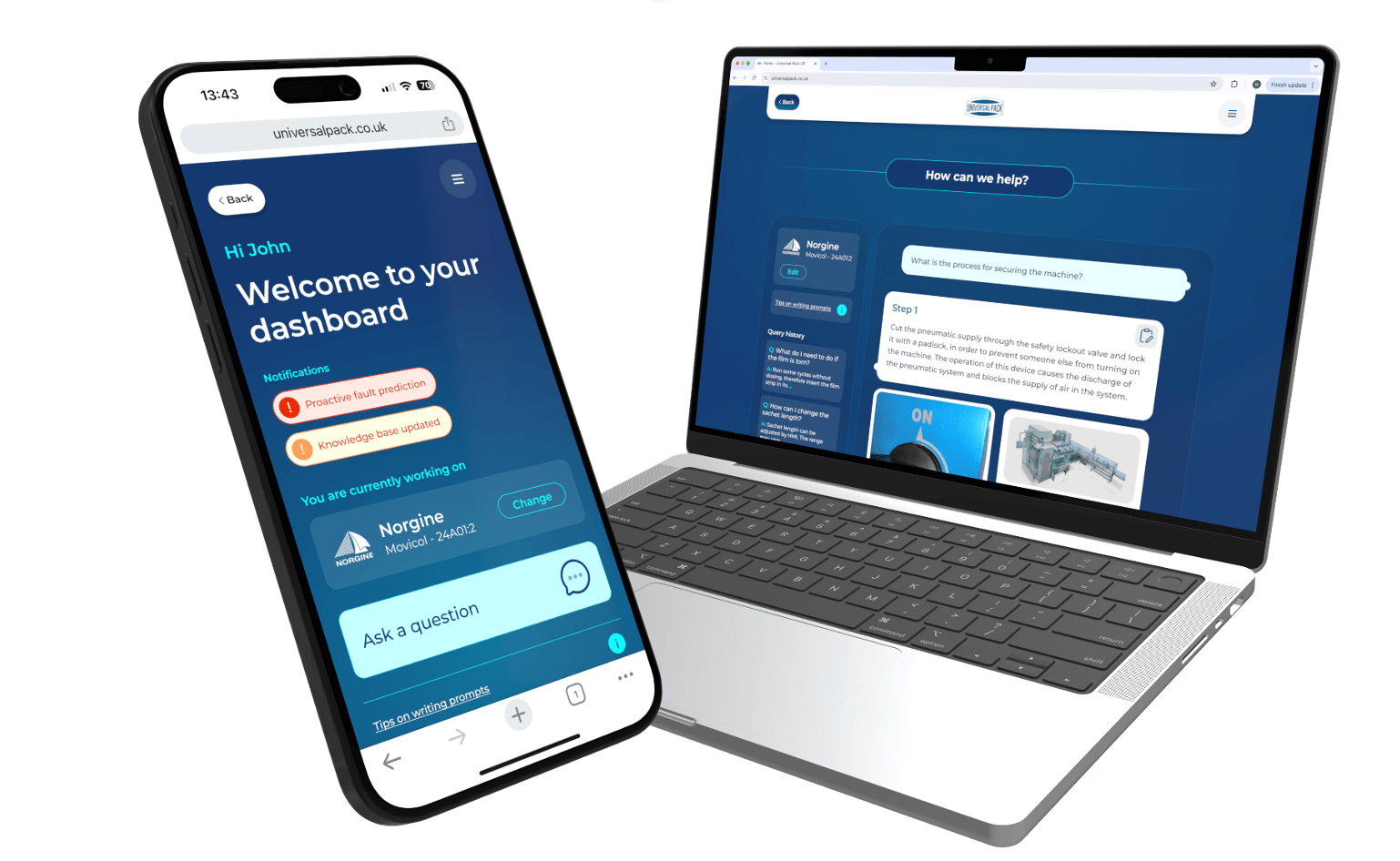

Our solution was a user friendly GenAI chatbot-style tool that helped engineers quickly identify and resolve issues by collating disparate business data and delivering real-time responses.

Built on their knowledge, their documents, their way of working. Like having Dave in your pocket, 24/7.

“We thought we were just mitigating the risk of one engineer retiring, but it turned into much more.“

Stephen Birnie – Head of Operations, Universal Pack UK

The results

Early testing showed instant success.

20% reduction in maintenance time

15% reduction in unplanned downtime

These cost savings meant Universal Pack could spend more time on planned maintenance and support work, charge their customers less for call outs, and, crucially customers had more uptime, which means more production time and more profit.

And that’s just the start. Universal Pack are also filling in their knowledge gaps. Collecting Dave’s 30 years of undocumented knowledge to improve their understanding of each machine.